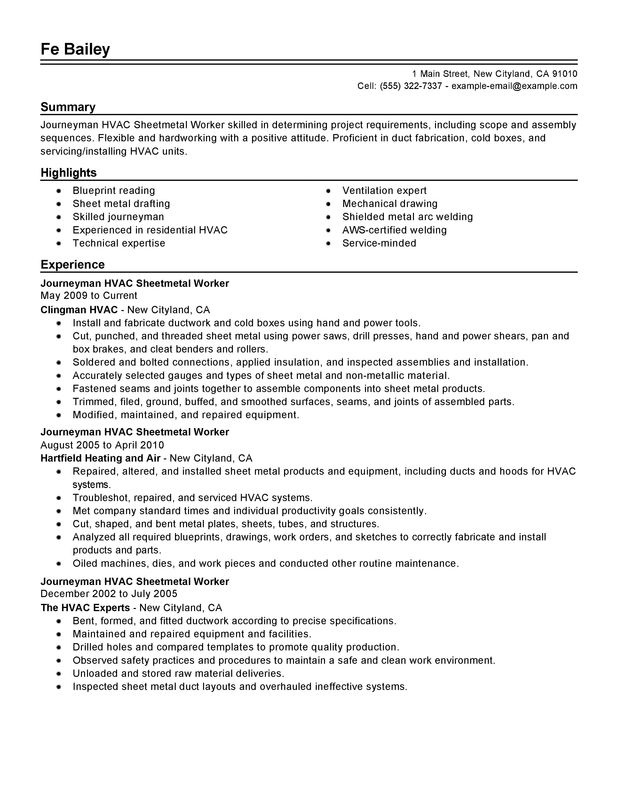

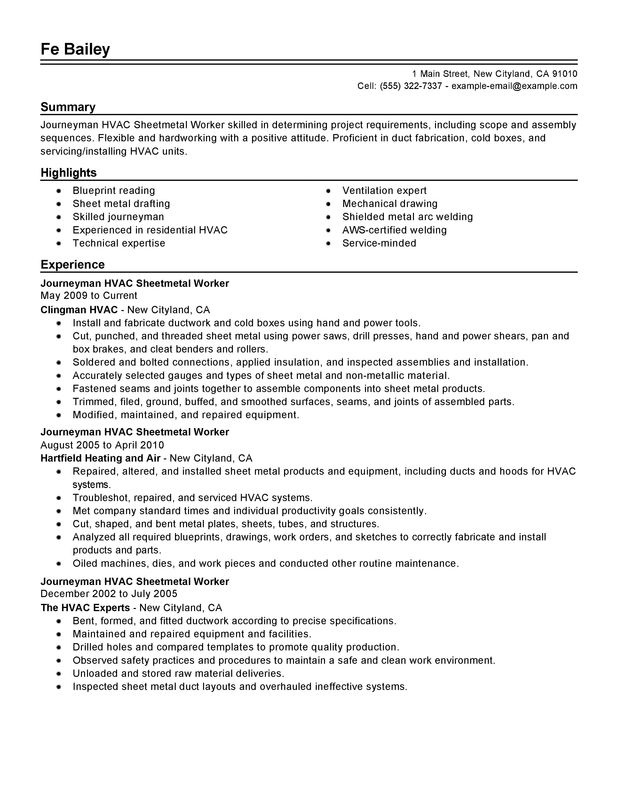

Screw the license plate onto the bracket.

Installing licensce plate onto sheet metal.

Vertical metal siding can give a building a modern sleek appearance.

To go along with.

To save time and labor you can use self drilling self tapping screws to drill into metal.

You can easily measure out a 12 x 6 rectangle on your sheet of metal using a ruler and marker and guess at the rounded corners.

Actually i got away with a warning but it could have.

I made a template out of cardboard but it s not necessary.

Install pop lights into bumper figure 4.

This is not the best approach because the metal will rust when embedded in concrete.

Once the bracket is in place you can align its holes with the holes in your license plate.

For thicker metal it may require more than one screw to drill through the surface.

Offence he will be delighted to add illegal plates onto the charge sheet.

There is no such thing as pressed metal plates that are legal.

While installing vertical metal siding is similar to installing horizontal siding there are a few differences you ll want to keep in mind.

Fortunately with the right tools and preparation putting vertical metal siding up on a building can be a smooth and simple process.

For those of you who were concerned about kevin and i running around illegally with no 3rd brake light or license plate light have no fear.

Using square plastic grommets and sheet metal screws install license plate see figure 3.

Mounting kit contents driver side mounting.

Steel can be attached to concrete without screws or glue by using concrete anchors and bolts.

The license plate frame i have will hold a plate and matches its stock bolt holes.

Drive the screws clockwise through the holes to complete installation.

If your product includes a license plate frame place it over the license plate and align its holes with those in the bracket and plate.

Using supplied connectors splice pop light wires into truck illumination wire as shown in figure 4.

Make sure license plate lights are working properly.

Alternatively you could cast the concrete with the metal embedded in the concrete.

Although these screws are more expensive they re capable of.

In this case there would be no way of removing it after it had rusted and broken down.